a thin piece of glass fiber (optical fiber) can transmit information equivalent to thousands of book s almost instantaneously to hundreds of kilometers away. In the modern communication industry, it has long replaced copper wire as the carrier of long-distance signal transmission. Since the advent of opt ical fiber in 1966, the initial goal of people's pursuit is to reduce the loss as much as possible. At th e end of the 1970s, optical fibers had reached only 4-5% energy loss per kilometer (0.2dB/km), and optic al signals could be transmitted for tens of kilometers. With the development of science and technology, e rbium-doped fiber amplifiers were put on the market in the late 80 s, and optical signals could be enhanc ed in the transmission process, completely solving the historical problem of optical fiber loss and realiz ing ultra-long-distance information transmission across oceans. As a dynamic emerging force in the communi cations industry, optical fiber has flourished. Therefore, Gao Kun, a Chinese scientist with the reputation of "the father of optical fiber", won the Nobel Prize in physics in 2009. Since 1990, due to the rapid growth of network data communication services, people's requirements for traditional communication sys tems have been continuously improved, and optical fiber communication systems with larger capacity, higher spe ed and longer transmission distance have emerged. However, in traditional optical fiber systems, there are pro blems such as dispersion, nonlinearity, and simple functions of logic devices in next-generation all-optical n etworks (such as optical switches), which require new optical fiber technologies and devices to support.

1. From Traditional Fiber to Photonic Crystal Fiber

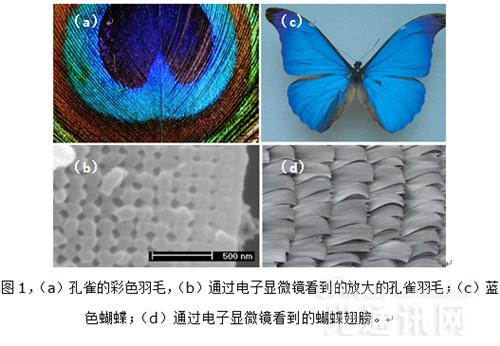

In 1987, scientists such as Eli Yablonovitch discovered that some animals have fine hairs arranged pe riodically and regularly, which can completely reflect light of certain colors (corresponding to a c ertain wavelength), and absorb other wavelengths to show gorgeous colors, as shown in Figure 1 The s urface of peacock feathers and butterfly wings shows bright colors. Eli Yablonovitch and others named s uch structures "photonic crystals". Soon, this structure was transplanted and applied in the field of optical fiber. In 1992, Phillip Russell and others proposed "photonic crystal fiber" (a type of micros tructure fiber). The photonic crystal fiber is composed of a cluster of small quartz capillaries arran ged periodically in a hexagon. From the cross section, it looks like a honeycomb structure. Due to its excellent transmission characteristics, photonic crystal fibers are rapidly receiving attention worldwide.

conventional optical fibers (such as Figure 2,(a)) is usually made of two glass materials, including a core with a higher refractive index and a cladding with a lower refractive index. The light propaga tes in the core of the high refractive index material in the form of total reflection. Photonic cryst al fiber can be made of a single material (such as quartz glass), divided into solid core and hollow cor e two structures. The structure of a solid-core photonic crystal fiber is usually an array of two-dime nsional capillaries composed of hexagons. The centermost capillary is replaced by a quartz glass rod, fo rming a defect of a photonic crystal (Figure 2 (B)), and light It propagates in this solid defect. The working principle of this kind of optical fiber is close to that of traditional optical fiber, and it pr opagates through different refractive indexes of the core and cladding. This is because the cladding co ntains air holes, so that the effective refractive index of the cladding is smaller than the refractiv e index of the core, and the light forms total reflection in the core. Hollow-core photonic crystal fibe r (Figure 2(c)) is also only one material of silicon dioxide, but it is completely different from tradi tional fiber and solid-core photonic crystal fiber. Hollow-core photonic crystal fiber adopts the princi ple of photonic band gap and uses photonic band gap effect to realize light transmission in air. Light pr opagates through the middle pores in this photonic crystal fiber, so there is no limitation of transmissi on window, loss, dispersion, etc. of conventional fiber.

2. Revolutionary Advantages of Photonic Crystal Fiber

In addition to the difference between photonic crystal fiber and traditional fiber in shape, photonic crystal fiber also has revolutionary advantages in design freedom. In addition to the characteristics of traditional optical fibers, photonic crystal optical fibers can also flexibly adjust the size, spacing and geometry of the hollow pores in the core or cladding. These changes make the optical fiber have more performance, and therefore surpass traditional optical fibers in many aspects. Here are a few simple examples:

(1) Single manufacturing material

First, a single material is not easily affected by temperature changes. If there are a variety of g lass materials in the optical fiber, and the thermal expansion coefficient of each glass is differen t, the transmission performance of the optical fiber under non-constant temperature conditions will change accordingly, which may cause signal disorder, and there is no different thermal expansion coe fficient of a single material optical fiber product, which avoids the limitation of temperature diff erence well, and the signal is more stable. Secondly, a single material has superior radiation resist ance. If traditional optical fibers are used in an environment outside the atmosphere, the core germ anium that has lost the protection of the atmosphere will be interfered by cosmic rays and produce ch emical changes, and the performance of the optical fiber will no longer be stable. The photonic crys tal fiber has only a single quartz glass and will not be disturbed by this situation. Moreover, the so lid-core photonic crystal fiber is made of pure quartz, and the porous structure of the outer claddi ng makes the effective refractive index of the cladding lower than the core, thus ensuring the continu ous transmission of light in the core. The spacing of capillary holes can also be designed to control the light pattern.

(2) air core transmission

In the hollow-core photonic crystal fiber, light is transmitted in the hollow core, avoiding the abso rption and scattering problems of the core material itself, so there is no transmission window in th e traditional glass fiber, the entire band can transmit light, and theoretically It can achieve extrem ely low loss. Although the loss of the current hollow photonic crystal fiber is greater than that of the traditional fiber due to the drawing defect of the hollow core fiber, with the gradual optimizatio n of the production process of the hollow photonic crystal fiber, this problem will be solved soon. A t the same time, the dispersion of hollow-core photonic crystal fiber is closely related to the cladd ing structure. Changing the structure of hollow-core photonic crystal fiber can make the zero dispe rsion wavelength move to the short wavelength direction, and can realize various special dispersion r equirements (such as dispersion flatness, dispersion compensation, etc.). In addition, when light i s transmitted in air, its nonlinear coefficient is very small, which is more than 1000 times lower tha n that of traditional single-mode fiber, which is conducive to suppressing harmful nonlinear effects.

(3) convenient production

Photonic crystal fibers do not require the use of large equipment such as chemical deposition to co mplete the manufacture of preforms. The conventional preparation method of optical fiber preform is the chemical deposition method in the tube. The preparation of a preform often takes several hours to tens of hours, and there are harmful gases. The photonic crystal fiber preform is completed by th e capillary tube arrangement method, and dozens or hundreds of capillaries are arranged in a honeycom b shape. No chemical deposition is required, production time is saved and no pollution to the enviro nment. With the gradual development of the market, production costs will also be greatly reduced.

3. The photonic crystal fiber developed and produced in China has reached the international advanced level.

The photonic crystal fiber produced in China has reached the international advanced level. Wuhan Chang yingtong Optoelectronic Technology Co., Ltd., the first special optical fiber industry company in Chi na, has developed polarization maintaining photonic crystal fibers of various sizes. The photonic cry stal fibers produced have reached the international advanced level, and are also steadily developing products such as photosensitivity and hollow photonic crystal fibers. The loss of polarization-mainta ining photonic crystal fiber produced by a domestic enterprise is less than 1.5dB/km in 1550nm band. The fiber cladding and core are made of the same material. The measured data show that its temperature sensitivity is better than that of the traditional polarization maintaining fiber, and the total temp erature extinction ratio changes to about 2dB, which has great advantages over the traditional polari zation maintaining fiber. Now, the company is conducting experiments on the fusion of photonic crystal fibers, which is expected to promote the practical process of photonic crystal fibers.

Optical fiber has been developed for more than half a century. For different applications, the material and structural design of optical fibers are evolving. The emergence of photonic crystal fiber has refr eshed optical fiber manufacturers and application providers. Its flexible structural design freedom h as also attracted strong interest from major scientific research institutes. Although there is a huge p otential market, there are only a handful of companies with photonic crystal fiber development and production capacity in China.